Chemical Engineering (December): 109. https://petrowiki.spe.org/w/index.php?title=Separator_sizing&oldid=48504, Copyright 2012-2023, Society of Petroleum Engineers. AH)0S A8N0R For illustration, the 50% water-cut map is shown in Fig. Liquid holdup and surge times Table 10. "(($#$% '+++,.3332-3333333333 " I think there should be some suitable and proper design guidelines available in your organization. Bothamley, M. 2013. For the past several years he has been a senior technical advisor for PetroSkills, a large technical training company that supports the oil and gas industry. *:JZjz ? Hence, a 24-in. gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3. 1Approximate shell length for vertical vessels (courtesy of CDS Separation Technologies Inc.). Typical retention time for 3-phase separator Table 7. Adobe d C The procedure then to calculate the drag coefficient is to calculate the Archimedes number, Ar, as defined in Eq. Continue with Recommended Cookies. A Separator is a pressurized vessel used in the exploration and production (E&P) of an oil and/or gas field to split a multi-phase well stream into a gas stream and one or more liquid streams. X"*WbA^@l'?iPsA#7*Q- 3(F d-fSXHlRzj;zK$`E@\LUr*.

However, the OIW specification is set at 2,000 ppmv and is not constraining separator size. Therefore, the internal diameter must be increased to reduce the Leff/D ratio. io(A "V _/)"6MaL)`/6 We and our partners use cookies to Store and/or access information on a device. Welcome to my space, I am Anup Kumar Dey, an experienced piping engineer for the last 19 years. Operating pressure and operating temperature. aL) S For the purposes of this article, the diverter plateconfiguration will be taken as representative of this group of inlet device types. vGo*nBG!iQiQiQ[jm endstream endobj 59 0 obj 382 endobj 64 0 obj << /Length 65 0 R /Filter /FlateDecode >> stream

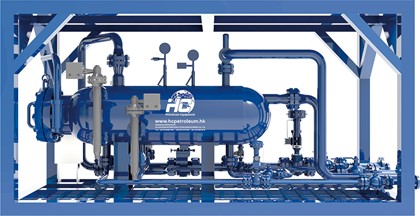

aH) T-PS The most common configuration of a 3-phase separator used in the separation process is shown in the following sample from Kimray Inc. : Other information that shall be remembered while designing the separator includes separation efficiency, capacity, and pressure drop. This is probably a reasonable assumption for most of the inlet device types, except for possibly the cyclonic inlet device, where the effect of the generated centrifugal forces should be expected to separate at least the larger water droplets from the oil, and oil droplets from the water, although to what degree this separation is undone due to turbulence associated with the combined oil/water mixture flow exiting the cyclone underflow is unknown. RE: Retention time for 3 phase separation in horizontal separators MortenA (Petroleum) 5 Feb 13 06:59 If you already know the size of the separator (and the weir height etc.

WebThree Phase Separators - Times Definition - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Calculate vessel diameter based on gas capacity from Eq. provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). *:JZjz ? WebTwo-Phase GasLiquid Separators. Liquid holdup and surge times Table 10.

! WebThree Phase Separators - Times Definition - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Step 3.  2. Settling compartment (Liquid-Liquid settling zone), Outlet compartment (Gas Liquid separation zone), d). Learn methods and guidelines for using stereolithography (SLA) 3D printed molds in the injection molding process to lower costs and lead time. Maurice Stewart, Ken Arnold, in Gas-Liquid And Liquid-Liquid Separators, 2008. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. Separators are classified into two-phase and three-phase separator. Too high of a gas velocity will result in liquid re-entrainment from the liquid surface, which may flood the demister and cause carryover. The purpose of this article and Part 1 is to illustrate a new methodology for sizing and rating three-phase separators that is based on quantifying the actual mechanisms and physics that govern phase separation performance in typically used equipment. Size a horizontal separator to remove 100 m drops in the gas phase. HN0G8I Operating pressure and operating temperature. aS aH) T-PS Recommended K value 41 . 3-Phase separator in horizontal orientation consists of a shell, dished ends, and mostly two saddles. Estimate overall volume based on the retention time and expected separation performance for each phase, and the major factors needed to be considered include: 2. However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. It must be noted that the quantification of actual velocity profiles and their variations is best done by computational fluid dynamics (CFD) modeling with validation via empirical testing. The vertical separator will tend to be influenced by wind and seismic load resulting in greater bending stress, and deflection. 8. The seam-to-seam length of the vertical vessel should be determined from the geometry, once a diameter and height of liquid volume are known. d- Oil temperature inside separator as per SWT operator in deg F. e - Liquid level should be(% percentage from min. JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K

endstream

endobj

74 0 obj

904

endobj

77 0 obj

<<

/Length 78 0 R

/Filter /FlateDecode

>>

stream

Some of our partners may process your data as a part of their legitimate business interest without asking for consent. 4. 8. Droplet size of liquid and oil to be removed. Calculate liquid levels for retention time based on Eq. Keskin et al. 27; solve Eq. WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. Since free water does not settle out in the time it takes for the oil and gas to separate, a three-phase separator requires a longer retention time than a two-phase separator. Meanwhile, three-phase separators are used to separate gas from crude oil and water component. In particular, quantification of dispersed phase droplet sizes and entrainment levels, in conjunction with the design aspects that influence them, are a key focus of this work. v. 2.X~f61c[H$NSb.(%_^

endstream

endobj

61 0 obj

94

endobj

58 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im7

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 59 0 R

>>

stream

2. Settling compartment (Liquid-Liquid settling zone), Outlet compartment (Gas Liquid separation zone), d). Learn methods and guidelines for using stereolithography (SLA) 3D printed molds in the injection molding process to lower costs and lead time. Maurice Stewart, Ken Arnold, in Gas-Liquid And Liquid-Liquid Separators, 2008. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. Separators are classified into two-phase and three-phase separator. Too high of a gas velocity will result in liquid re-entrainment from the liquid surface, which may flood the demister and cause carryover. The purpose of this article and Part 1 is to illustrate a new methodology for sizing and rating three-phase separators that is based on quantifying the actual mechanisms and physics that govern phase separation performance in typically used equipment. Size a horizontal separator to remove 100 m drops in the gas phase. HN0G8I Operating pressure and operating temperature. aS aH) T-PS Recommended K value 41 . 3-Phase separator in horizontal orientation consists of a shell, dished ends, and mostly two saddles. Estimate overall volume based on the retention time and expected separation performance for each phase, and the major factors needed to be considered include: 2. However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. It must be noted that the quantification of actual velocity profiles and their variations is best done by computational fluid dynamics (CFD) modeling with validation via empirical testing. The vertical separator will tend to be influenced by wind and seismic load resulting in greater bending stress, and deflection. 8. The seam-to-seam length of the vertical vessel should be determined from the geometry, once a diameter and height of liquid volume are known. d- Oil temperature inside separator as per SWT operator in deg F. e - Liquid level should be(% percentage from min. JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K

endstream

endobj

74 0 obj

904

endobj

77 0 obj

<<

/Length 78 0 R

/Filter /FlateDecode

>>

stream

Some of our partners may process your data as a part of their legitimate business interest without asking for consent. 4. 8. Droplet size of liquid and oil to be removed. Calculate liquid levels for retention time based on Eq. Keskin et al. 27; solve Eq. WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. Since free water does not settle out in the time it takes for the oil and gas to separate, a three-phase separator requires a longer retention time than a two-phase separator. Meanwhile, three-phase separators are used to separate gas from crude oil and water component. In particular, quantification of dispersed phase droplet sizes and entrainment levels, in conjunction with the design aspects that influence them, are a key focus of this work. v. 2.X~f61c[H$NSb.(%_^

endstream

endobj

61 0 obj

94

endobj

58 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im7

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 59 0 R

>>

stream

In vertical vessels, settling theory results in a relation for the vessel diameter. AH)0S0S Separator K value Table 9. Pressure vessels where weight savings are a critical factor such as offshore or marine applications. AH) _ /B *:JZjz ? Used for large surge volumes because of its most efficiency large amounts of dissolved gas are present with the liquid, The horizontal separator has a greater capacity, Can add an additional boot to achieve liquid/liquid or vapor/liquid separation efficiency, A less static head affects the supports geometry. Adobe d C Properties (density, viscosity) of oil and gas, respectively. By Mark Bothamley. For screening purposes, the following approximations can be used. If the liquid level is too high, the demister will not drain, and liquid siphoning can occur. :~>\ri\;KTK8@Z}5EBxi+].g9PF#N[vlWM&s2qe}B,.="QUWe5hds52|f]rP!M&})kfryLq*=LK81*$PgPg.4 N34 The gas velocity across the oil surface is only at approximately 27% of the re-entrainment velocity. Hi,Please refer to API Spec 12J for your guidelines and Surface Production Operations Design of Oil Handling and Facilities Vol 1 3rd Edition, Elsevier, 2008 Handbook. N37{=*l(?X]s}=r[E *T endstream endobj 20 0 obj 186 endobj 10 0 obj << /Type /Page /Parent 5 0 R /Resources << /Font << /F0 6 0 R >> /XObject << /im1 11 0 R /im2 15 0 R >> /ProcSet 2 0 R >> /Contents [ 13 0 R 17 0 R 19 0 R ] >> endobj 24 0 obj << /Length 25 0 R /Filter /FlateDecode >> stream At first glance, this seems counterintuitive. AH)0S "Prejudice" is having an opinion not supported by the preponderance of the data. Web3-Phase Separators: An Overview. This device is designed according to the process requirement, and attached inside the separator by either welding or bolting connections and usually will be finalized by an internal Vendor (e.g from Sulzer) and approved by their Principal. WebThere is a procedure to design three phase separators . a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy 9. This area in particular will benefit from further CFD/empirical testing, which allows better tuning of models as described here. Typical retention time for 3-phase separator Table 7. H} 0 n/@HNq"zv` _pEn,=R7H When using settling theory or demister sizing in horizontal vessels, one should also consider the gas velocity for re-entrainment. Low liquid level height Table 11. Related equation that I found important have been attached in the spreadsheet. Table 4 shows Leff/D for three different vessel IDs. The use of the Code shall be limited to the following pressure such as: If any of the following conditions apply, the vessels should be constructed in accordance with Division 2, unless otherwise specified by the Company. Typical retention time for 3-phase separator 40. "(($#$% '+++,.3332-3333333333 " A design review of an oil and gas project is a comprehensive evaluation of the technical design and engineering of the project, aimed at identifying any potential issues or risks that could impact Hi There! 5. AL)0_S An example illustrates the calculations needed to achieve the specified outlet fluid qualities. a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy Theory for Hopper Sedimentation, 29th Annual Texas A&M Dredging Seminar, New Orleans, June. AH)0@0S Table 7. Already a member? Table 8. Washington, DC: API. aH) _R aL) S Retention time utilizes time to aid separation.

Web> stream "", To view or add a comment, sign in Moshfeghian Calculate the required mesh-pad area with Eq. 4.

6- If time not as per point 2 , SWT operator need to do the needful to increase retention time; increase level, heating, chemical injection,etc. and for specific cases affects the impact test requirements (e.g per UG-20(f) and UCS-66 from ASME VIII Div.1). A small hole is sometimes drilled into the drainpipe as a siphon breaker. Oil and Gas Fac. Olotu, C.O. 1Three-phase flow patterns (Keskin et al. ..(25) Table 7 shows liquid levels for different vessel diameters. Liquid retention time for 2-phase separator Table 6. Hu D^pnkbrlc/@1mcHfay;CMuK.J(fHfh!31,%2V/,$_P^p aH) _R L/D ratio Table 12. <> JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K endstream endobj 16 0 obj 904 endobj 19 0 obj << /Length 20 0 R /Filter /FlateDecode >> stream 8. gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3. WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. Part 2 of this two-part series presents a new methodology for sizing and rating three-phase separators based on quantifying the actual mechanisms and physics that govern separation performance. The vessel diameter is then obtained as. For three-phase separators, the ratio is in the 1.5 to 3 range. aH) _R The output size consists of diameter and length/height (seam-seam) depending on the gas capacity or liquid capacity calculation. (or consistent units for, fractional continuous-phase cross-sectional area, fraction of vessel cross-sectional area filled by liquid. SPE-161036-PA. http://dx.doi.org/10.2118/161036-PA. Use this section to provide links to relevant material on websites other than PetroWiki and OnePetro. As has been shown in this article, reduced feedpipe diameter will increase fluid velocities, reduce droplet sizes, and increase entrainment which will make subsequent phase separation more difficult. An example of data being processed may be a unique identifier stored in a cookie. If this data is not available, approach in table below can be used for estimation. Adobe d C Reasons such as off-topic, duplicates, flames, illegal, vulgar, or students posting their homework. Good contents.Keep the good work for upcoming article. Calculate the required mesh-pad area with Eq. Retention time utilizes time to aid separation. WebThere is a procedure to design three phase separators . This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more.

6 for a 500-m drop. Promoting, selling, recruiting, coursework and thesis posting is forbidden. Adobe d C Web3-phase separators: separate the gas from the liquid phase, and water from oil. Table 3 gives guidelines that can be used for sizing nozzles, where m is the bulk density and Vm the bulk velocity. AH)0S AH)%%$8N$/I AL)0_S Gas-Liquid SeparatorsQuantifying Separation Performance Parts 13, SPE Oil and Gas Facilities, AugustDecember. WebThere is a procedure to design three phase separators . It is also called as free-water-knockout. AH)%%$8N @/P The working principle for spherical three phase separator is quite similar to horizontal and vertical phase separators. Calculate liquid levels for retention time based on Eq. JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K endstream endobj 63 0 obj 904 endobj 66 0 obj << /Length 67 0 R /Filter /FlateDecode >> stream Table 9. L/D ratio Table 12. ! An example of the pressurized vertical and horizontal separators used in separation & processing include: Mechanical Design of the separator is done following ASME BPVC Sec. 8 0 obj << /Length 9 0 R /Filter /FlateDecode >> stream A bigger area is required but with less climbing ladder & platform. At this point, we know that the water-drop removal is the dominant sizing parameter in comparison to the gas capacity. Lets briefly look at the common design factors of a separator below. AH)0S0S To size horizontal three phase separator, we need the following data: A certain amount of oil storage is necessary to ensure that the oil reaches equilibrium and flashed gas is liberated. Table 1 shows physical properties of three phase and the mass flow rates at the inlet. 2.13. ho = 74 in. A8N0R ! "(($#$% '+++,.3332-3333333333 " It can be used for two or three phase separation process. AH) _ /B Your email address will not be published. ! The selected vessel would then be 24 in. Step 8: Calculate slenderness ratio (12 L ss Operating pressure and operating temperature. effective length of the vessel where separation occurs, ft, continuous-phase velocity, m/s (or consistent units for, specific gravity difference (heavy/light) of continuous and dispersed phases, continuous phase viscosity, g/(cm/sec) = poise. Given Values. aL) S aL)0_(,R July 18, 2017. The approach used here, and in the Excel spreadsheet, is approximate only.Regarding Item 4, the effective release point, the same assumption has been made for all inlet types: the dispersed phase is released uniformly over the vertical height of the continuous phase at the centerline axis of the vessel at the start of the gravity separation sectionbasically at the perforated plate location. Fig. link to Importance of Pipe Fabrication Shops in Piping Construction for Oil and Gas Industries: Shop Fabrication vs Site Fabrication, link to What is Design Review? With a strong will to strengthen himself and others, he started to share his hobby through sharing knowledge and writing article. AH) eR p' pl/[ Select vessel that satisfies both gas and liquid capacity. The vessel diameter of approximately 11 ft is driven mainly by the following factors: The calculated corrected residence times (adjusted for nonuniform velocity profiles) for the oil and water phases look reasonable in comparison to the calculated separated phase qualities: The calculated separable droplet sizes (100% removal) for each liquid also look reasonable.The use of a multivane inlet device combined with perforated plates has a beneficial effect on the phase velocity profiles/flow distributions which helps gravity separation performance significantly.

provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). AH)0@0S AH)0S0S The oil drops to be removed from the gas stream also depend upon the downstream equipment. Calculate the vessel diameter based on water drop removal from Eq. AL)0_S -T!G eJJXQ\ /X\YV`3 f]=tK In horizontal vessels, a simple ballistic model can be used to determine a relationship between vessel length and diameter. vGo*nBG!iQiQiQ[jm endstream endobj 70 0 obj 382 endobj 75 0 obj << /Length 76 0 R /Filter /FlateDecode >> stream The first step in oil and gas production is to split the flow up into its individual components with a separator. ..(25) Table 7 shows liquid levels for different vessel diameters. AH)%%$8N$/I The first step in oil and gas production is to split the flow up into its individual components with a separator. AH)0S0S 8. HVMoFsTPH{H\(zI"_C)5;;K1\h>S7 To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. Droplet size of liquid and oil to be removed. 35 % to max. Adobe d C However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m Produced well fluids consist of various amounts of oil, water, natural gas, and sediment. To calculate (liquid) retention time for a two-phase separator divide the liquid volume inside the vessel by the liquid flow rate, these values are normally in the range 1-3 minutes depending from application. In this case you have to calculate the curve area. aL)0_(,R Droplet Size: 500 microns. 1Three-phase flow patterns (Keskin et al. The type of inlet device utilized impacts separator size and performance in four main ways: These topics have been covered earlier in this article. Values for 12 Lss /d should be in the 1.5 to 3 range. Field experience indicates that oil content in the produced water from a three-phase separator, sized for water removal from oil, can be expected to be between a few hundred and 2000 mg/l. a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy aL)0_(,R