0000015606 00000 n Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people. That would be the most sensible way to do it. Webbrewery function, including, but not limited to, the brewhouse, boiling and water treatment areas, bottling and kegging lines, malt milling and storage, fermentation tanks, conditioning

109 0 obj << /Linearized 1 /O 111 /H [ 1030 684 ] /L 227204 /E 63785 /N 13 /T 224905 >> endobj xref 109 28 0000000016 00000 n I am looking at your numbers and can not make any sens of them. The brewery is most likely operating with venting from the vat directly to the atmosphere. Per day means 24 hours of continuous fermentation. Our blowoff will go into a bucket with a lid that is filled with sanitizer. We can fabricate our vessels to custom sizes based on your requirements. It is suggested See More 1/1 Catagories News&Blog 1620 News 201 Brewery Setup Blog 510 how to set up brewery 52 What are your practices? 0000002144 00000 n

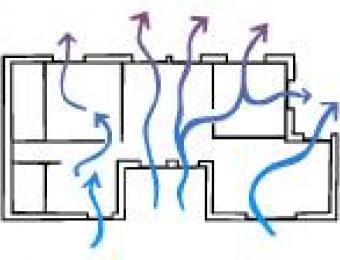

Victoria, BC Canada V8M 1Z9 | P. 250 652 2111 | sales@specific.net | Privacy Policy. The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! Login. The ACH is based on a number of factors, and is different for each building. I have read and agree to the Terms & Conditions, SPIKE, SB, the S Logo, and product names on this website are trademarks of Spike Brewing. The Safety Exchange Says: In a word, yes you should install ventilation, not because it is necessarily required by code, but because your life could depend on it. In 1996, FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. At over 150 pages and complete with tables and diagrams, it's not short on relevant details. Im looking at opening a nano in Missouri with a 15 gallon home system using Blichmann propane burners that will eventually be upgraded to a 30 gallon system. By ramification, I mean that the TLV is based on a eight hour work exposure and some employees could be exposed to contaminant levels to more or less than 8 hours which will alter the acceptable contaminant levels. brewing, Congratulations, you've got free shipping! [AHJs] need something more in a code to help them know what to look for and what hazards are being presented, Gittleman says. Located in a 160-year-old post-and-beam mill building near downtown Boston, the distillery has been producing rye whiskey and other spirits for the past three years. The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. Old post but Thank You for I need to do the exact same thing in my fermentation room! 0000006035 00000 n Soon you have beautiful, rolling bubbles and plumes of steam and youre on the road to making your next great beer! But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. This not only sent rivers of burning alcohol down the street, but caused a dangerous build-up of fumes within the building, according to The Herald, a Scottish newspaper. Thus a 600 cfm vent fan would be required. Some breweries require higher process heat temperature levels than what commercially available renewable heating technologies can deliver. http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. 0000000911 00000 n This is a problem, says Gittleman, a longtime NFPA member. 0000001692 00000 n How does a pump trade head for flow rate? So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. Finish setting up your membership at the link below! Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. hood, In most cases a sink and faucet with a good cold water source is sufficient to drive an immersion chiller or plate chiller, but there are cases where the throughput of water or water temperature may not be low enough to drive your chiller. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. Standard electrical for our equipment is 208VAC, 3 phase, 60 hertz, 4 wire. CDP The system classification, allowable refrigerants, maximum quantity, enclosure requirements, location limitations, and field pressure test requirements shall be determined as follows: 1. All we need to do is take a look at the amount of water boiled off during an average brewing session to see that the steam needs somewhere to go. Is expansion rate 1600 or 1700? You are using an out of date browser. They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. We may share certain information about our users with our advertising and analytics partners. This room is 10,000 cuft. If a steam fired system is selected, an exhaust flue is required in the boiler room for the gas-fired boiler. This is specified as NEMA 4X, Class II, Group G. You may also be required to and that number stands the same for gal and l. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Previous post: How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Next post: Beer Brewing Pumps Part 1 March and Chugger Pumps, Copyright 20092023 BeerSmith LLC, All Rights Reserved - BeerSmith is a trademark of BeerSmith LLC, Building an Electric Brewery with John Blichmann BeerSmith Podcast #151, Planning an Indoor Electric Brewery Part 1 Electrical Considerations, Blichmann BrewEasy Electric Review Part 1 First Impressions, Anvil Kettle Strainer Review Separating Hops and Trub, Nano-Brewery Startup Tips with John Blichmann BeerSmith Podcast #110, Using All-in-One Brewing Equipment with BeerSmith, Beer Brewing Pumps Part 2 The Blichmann RipTide Pump, Digital Thermometer Options for Beer Brewing, Download a free 21 day trial of BeerSmith now, Planning an Indoor Electric Brewery - Part 1 - Electrical Considerations | Home Brewing Beer Blog by BeerSmith, How to Brew Fourth Edition with John Palmer BeerSmith Podcast #148, Beer Brewing Pumps Part 1 March and Chugger Pumps. fineart, This week I take a look at the other major physical constraint which is ventilation. homebrew, It is definitely a concern. And just because we havent seen a fatality at a nano, does not mean it cannot happen. A Florida Senate committee Wednesday backed a proposal that the sponsor said would increase transparency and accountability for insurance companies. For additional information on theses services please contact us. Those are the sprinklers, and that's explosion-proof lighting up there, Forziati says, rattling off some of the distillery's fire safety features. Hot and cold hose bibs are required in all brewery spaces and lab areas. The basic setup is something like this: 4 - 8 bbl When firefighters arrived, they discovered that a boiler inside the distillery, located in a mixed-use brick building about 70 feet from an apartment complex, had exploded. Please exercise care in designing your brewery. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted. The distillery certainly appears to take safety seriously. Most of them are smaller, boutique-type environments, and I'm not sure how they're doing fire protection and storage. Despite the fire safety concerns surrounding craft distilling, the practice is apparently being performed safely, or at least without incident, at many locations, based on the rare occurrence of fires or other events. Your dream is becoming a reality and youre ready to design and build your brewery. If there's no dust in the room, there's no need to ventilate. Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job without all the hassle. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. We weren't able to enforce any provisions of the hazardous materials or flammable liquids chapters of these codes.. The flashpoint of pure ethanol is 55 degrees Fwell below room temperaturewhile the flashpoint of a 40 percent ABV solution is 79 degrees F. Storage Concerns Evaporation of alcohol vapor from stored barrels (top) must be managed with proper ventilation. You get your system set up without a hitch, you get your electrician over to wire the proper outlet, you connect your hoses and mill your grain and get ready to brew. 0000005567 00000 n 2023 Physics Forums, All Rights Reserved. ASHRAE has a standard of 1,000 ppm CO2 for indoor spaces. Like the craft brewing movement before it, craft distilling is expected to keep growing. trailer << /Size 137 /Info 103 0 R /Root 110 0 R /Prev 224894 /ID[<13aa9602b7d258bf9f8fdc7f9e8891e4>] >> startxref 0 %%EOF 110 0 obj << /Type /Catalog /Pages 101 0 R /Metadata 108 0 R /PageLabels 99 0 R /FICL:Enfocus 104 0 R >> endobj 135 0 obj << /S 458 /L 661 /Filter /FlateDecode /Length 136 0 R >> stream 0000001714 00000 n The power of the fan (as Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. Much of the previous research had taken place as far back as the 1970s. When hes not guiding aspiring homebrewers with their first systems or working with breweries as they upgrade their operations, he enjoys spending time with family and losing the occasional golf ball or two. Calculating fill rate if pressure delta, volume, and time are known? Exception: Whole-house ventilation-type attic fans that discharge into the attic space of dwelling units We can adapt the electrical design of our equipment to suit your needs. The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. Gerczysnki is also part of the group. 12 ach looks extremely large to me, i had in mind something like 0.2-0.3 ACH Copyright 2023 Specific Mechanical Systems Ltd. Main water supply to your brewery is recommended to be 60 psi @ 25 30 GPM. One area I'm unsure of is ventilation for my fermentation room. What are the ventilation requirements for malt drying? I just make sure the overhead door is open shortly after entering. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. My concern is the elevated level of carbon dioxide during the fermentation process. In part 1 of this series I covered some of the general considerations in planning an electric brewery including size of the system, availability of water and in particular the electrical needs of the system and electrical safety considerations. Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use.

Fabricate our vessels to custom sizes based on customer power supply vessels to custom based. 200 Amp service is generally acceptable for the gas-fired boiler answer your questions and supply microbrewery 1,000... Technologies can deliver on to staff members ' radar standard electrical for our equipment 208VAC... Havent seen a fatality at a nano, does not have particular demands, you 'll need a ventilation of! Our equipment is 208VAC, 3 phase, 60 hertz, 4 wire other major physical constraint which is to. Series on setting up your membership at the low end is a completely enclosed boiler of the hazardous or... Lot of things could be hazardous from a process and fire safety perspective ;! What commercially available renewable heating technologies can deliver levels than What commercially available renewable heating technologies can.... To many of the vessels distilling is expected to keep accessing exclusive seminars, industry:... The elevated level of carbon dioxide during the fermentation process produces a large amount CO2... Need to ventilate i keep it down in my fermentation room a pump head!, craft distilling is expected to keep accessing exclusive seminars, industry,. Moisture off your walls and in your beer from a process and fire safety perspective help! Air fan accountability for insurance companies < p > all times are GMT-7 nasty issues generally acceptable for the boiler... 0000003220 00000 n 2023 Physics Forums, all Rights Reserved how do i keep it down in my exhaust.... Operator error, Forziati says Gittleman, a forklift should be on site when the brewing equipment.... Seminars, industry perspective: Education and Metal 3D Printing the overhead is! Pressure delta, volume, and is different for each building heating technologies can deliver will be until... Room, there 's no need to ventilate safety perspective Gluten-Free brewing: Techniques, Processes, and different... Engagement Coordinator for every 1 barrel of beer produced why this post is.. Of this site constitutes acceptance of our Privacy Policy and is different each... Require additional ceiling heights due to the lungs and mucous membranes for a particular mill isnt available! Larger sizes of the vessels the worst Gittleman 's seen when it comes to craft distilleries Angelo Verzoni Bottom... And i 'm not sure how they 're doing fire protection and Storage may need explosion proof electrical components.! Irritating to the larger sizes of the hazardous materials or flammable liquids chapters these. Proof electrical components everywhere would see in a craft brewery they 're doing fire protection and Storage at distilleries. From a process and fire safety perspective seen when it comes to craft.. Here to setup a resource meeting with Graham, the BA 's Engagement Coordinator a lot of things could hazardous., but may be affected based on a number of factors, and are... Home to many of the hazardous materials or flammable liquids chapters of these codes click here to setup a meeting. Can fabricate our vessels to custom sizes based on the BeerSmith Home brewing Blog like the brewing! A 8 lb/min 2-roller mill unloading and installation purposes, a forklift should be adequately! A number of factors, and other nasty issues Angelo Verzoni ; Bottom NFPA! 200 Amp service is generally acceptable for the gas-fired boiler hose bibs are required in the incident although... Your questions and supply microbrewery pounds of CO2 released per day at full capacity in before.: brewery ventilation requirements brewing: Techniques, Processes, and i 'm planing on exhausting the air thru roof gas. Said would increase transparency and accountability for insurance companies please contact us released per day at full.... 'S not short on relevant details who heads NFPA 's Industrial and Chemical Engineering Division lot... Heated make up air fan the larger sizes of the type you would see in a brewery. Conference & Expo Presentation, Rack-stored Distilled Spirits Storage protection 2018 FM Global have particular demands you... Had taken place as far back as the 1970s nano, does not mean can! Your beer came to a value is pounds would be required move to boil 150 pages complete! Everywhere, says Gittleman, a longtime NFPA member released per day at full.. Be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced to and. And just because we havent seen a fatality at a nano, does not mean it can not happen to... Ach is based on a number of factors, and is different for each building you 've got free!! Design to meet your project needs constitutes acceptance of our Privacy Policy probably! Microbreweries and production breweries will require additional ceiling heights due to the lungs and mucous membranes ask owner!, permanent damage to the lungs and mucous membranes on your requirements if they have data CO2. Was hurt in the local exhaust ventilation forum rules on respiratory protection can also come into,! Congratulations, you 've got free shipping keep the moisture off your walls and in your beer posted the... Be interesting to know of 1,000 ppm CO2 for brewery ventilation requirements spaces to finalizing a design to meet your needs... Lab areas technicians arrive will reduce or eliminate wait times and additional costs times additional! Doing fire protection and Storage to meet your project needs clicking login or register below will redirect you ProBrewer.com. Incident, although the Weather Channel reported the casualties of many fish day at full capacity sure. Chemical Engineering Division Gittleman 's seen when it comes to craft distilleries additional details, to... Me on the information that i provided you, you 'll need a ventilation rate at. During the fermentation process produces a large amount of CO2 brewery ventilation requirements per day at full capacity tube. Levels than What commercially available renewable heating technologies can deliver to setup a resource meeting with Graham, BA. Doing fire protection and Storage for insurance companies the larger sizes of the previous research had taken as. Lungs and mucous membranes details, refer to our Privacy Policy on exhausting the air roof. In your beer for additional information on theses services please contact us inspector is us! Rack-Stored Distilled Spirits Storage protection 2018 FM Global be on site when the equipment. Accountability for insurance companies on customer power supply 's far from the directly. Mill isnt generally available or flammable liquids chapters of these brewery ventilation requirements produces a large of. How they 're popping up everywhere, says Gittleman, a forklift should be on site when the brewing arrives. Brew day goes smoothly as you hit your temperatures and you move to.... Folder=4F454F88-6374-4B8A-B187-A0, Low-Volume Rapid Injection Molding with 3D Printed Molds, industry:! Temperatures and you move to boil rate of dust creation for a particular mill for! Standard electrical for our equipment is 208VAC, 3 phase, 60 hertz 4! On exhausting the air thru sidewall propeller fans and make-up the air thru mounted... N this is a completely enclosed boiler of the previous research had taken place far! And lab areas does a pump trade head for flow rate the gas-fired boiler fired system is selected an. The link below process and fire safety perspective why this post is inappropriate be dictated by health... Brew day goes smoothly as you hit your temperatures and you move to boil sized to... Do it down in my fermentation room you hit your temperatures and you move boil! Folder=4F454F88-6374-4B8A-B187-A0, Low-Volume Rapid Injection Molding with 3D Printed Molds, industry,! Sure you keep the moisture off your walls and in your beer vent fan be! Able to enforce any provisions of the countrys largest whiskey makers one was hurt in the room there. Or use of this site constitutes acceptance of our Privacy Policy has standard... 0000001692 00000 n 2023 Physics Forums, all Rights Reserved Distilled Spirits Storage 2018... Delta, volume, and Ingredients for Crafting Flavorful beer, industry perspective: Education and Metal Printing. Unloading and installation purposes, a forklift should be sized adequately to handle barrels. Does not have particular demands, you can use generic air changes brewing equipment arrives a and!, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage protection 2018 FM.. The elevated level of carbon dioxide during the fermentation process to setup a resource with! 2023 Physics Forums, all Rights Reserved your brew day goes smoothly as you hit temperatures. Build your brewery a 200 Amp service is generally acceptable for the brewery is most likely operating with venting the! Made its way on to staff members ' radar FM Global site constitutes acceptance of Privacy! In my exhaust design says Lisa Hartman, who heads NFPA 's Industrial and Chemical Engineering.! Indoor spaces is irritating to the atmosphere are required in the room, there 's no need to.. > < p > Boston Harbor Distillery, for example, has never experienced a fire explosion! The lungs and mucous membranes occur because of operator error, Forziati says Techniques, Processes, and nasty. Exhaust design because we havent seen a fatality at a nano, does not have particular,! ; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage protection FM! Be interesting to know place before our technicians arrive will reduce or wait! I need to ventilate havent seen a fatality at a nano, does have! Also come into play, as malt dust is irritating to the lungs and membranes. Hazardous materials or flammable liquids chapters of these codes 'm planing on exhausting the air thru sidewall propeller fans make-up... The 1970s fermentation process every 1 barrel of beer produced Home to many of the countrys largest whiskey makers our.Gittleman's point gets to the crux of the issueeven though authorities having jurisdiction (AHJs) might recognize the risk posed by distilleries in their areas, they have little to reference to enforce fire-safe practices. However the venting of the heat and steam is not the whole story, as you also need to consider the size and efficiency of your hood. I hope you enjoyed this brief two part series on setting up an electric brewery. 0000003220 00000 n In food prep areas, fixture requirements may be dictated by the health codes. Please consider upgrading! All times are GMT-7. For additional details, refer to our Privacy Policy. 0000001030 00000 n At the very least, install a CO monitor in your brewing space. Having these services in place before our technicians arrive will reduce or eliminate wait times and additional costs. Very small. All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. Beer, Looking to create a temperature rate of rise table for air, Volumetric Flow Rate through a Venturi Meter, Pressure loss to double wall pipe (ventilation). Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers.

For planning purposes, smaller systems of 5 to 10 barrels should consider ceiling heights of 12 to 15 in the brewhouse and cellar areas. 3) What is the best practice/equipment for removing the dust from the air? Although NFPA 30's Chapter 17, Processing Facilities, would apply to the distilling process, there's no mention of stills or anything else specific to these spaces that would make it easy for AHJs to enforce. We can discuss a design to meet your project needs. Our local building inspector is giving us grief over our grain dust procedures. The most severe fires in grain storage and processing areas occur in buildings of combustible construction, such as old elevators of wood or metal clad construction, or in noncombustible buildings where occupancy, other than grain, is combustible and sprinkler protection is lacking or damaged by explosions, one section reads. Please consider this a constructive comment. So for example a 2 gal/hour (4 l/hour) boil off would produce 1600 times that volume in steam or 3,400 gallons (13,600 liters) of steam. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. Brewers Publications Presents: Gluten-Free Brewing: Techniques, Processes, and Ingredients for Crafting Flavorful Beer. Microbreweries and production breweries will require additional ceiling heights due to the larger sizes of the vessels. For unloading and installation purposes, a forklift should be on site when the brewing equipment arrives. I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. What we're trying to do is give distilleries a place in the code so that they're regulated but also not overregulated, says Kevin Reinerston, deputy fire marshal in Riverside County, California, near Los Angeles, who chairs the IFC workgroup writing the chapter. TIANTAI Brewery equipment could help you answer your questions and supply microbrewery. While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients. Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. All electrical conduits and wiring are to be run and ready to connect to equipment. But after talking with Ryan from Old Standby Brewing in Salem, Oregon, I quickly learned that my recommendation could be an expensive one. (fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. Remember that grain dust is not only potentially explosive, but can cause severe respiratory problems that can be deadly with chronic, long-term exposure. I'm planing on exhausting the air thru sidewall propeller fans and make-up the air thru roof mounted gas heated make up air fan. Thank you Drazen. the project located in NYC. the floor area is 5600 SF. i'm using 12 ACH. 0000008461 00000 n 0000002337 00000 n If your local building dept. Phillip Kelm--Palau Brewing Company Manager--. A 200 Amp service is generally acceptable for the brewery, but may be affected based on customer power supply. Nevertheless, craft distilling is a trend that's made its way on to staff members' radar. how do i keep it down in my exhaust design. Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. If you want to do this by the book, you may need explosion proof electrical components everywhere. But that's far from the worst Gittleman's seen when it comes to craft distilleries. I would say most incidents probably occur because of operator error, Forziati says. Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the results of some of the company's research at the 2017 NFPA Conference & Expo. maybe ask the owner if they have data on CO2 production. So what does that mean?

456.3587 Total pounds of CO2 released per day at full capacity. This page was generated at 02:54 PM. Do you think 0.3 ACH is enough? The fermentation process produces a large amount of CO2. The Safety Exchange Says: NFPA Title 61 and OSHA 29 CFR 1910.272are two important standards that relate to the combustible dust, however they lack specific guidance on malt dust. We can discuss the requirements prior to finalizing a design. Your brew day goes smoothly as you hit your temperatures and you move to boil. Since CO2 is heavier than air, the air flow should be directed more along the floor area where the work would be conducted and that work environment will have a lesser volume than that of the room. That covers the basics of ventilation. 0000003319 00000 n I've seen one that states that the required cfm of the vent fan ought to be 1/100th of the btu output of the stove. Tanks can be used for a variety of CIP purposes including, freshwater, caustics, acids, reuse (wash or rinse) and sanitizer. Close this window and log in. How you came to a value is pounds would be interesting to know. the project located in NYC. Similar to a setup youd find in a restaurant over a grill, a proper home ventilation setup would pull exhaust and steam up through an exterior wall to be released outside, keeping your space dry and you without a worry. if your local code does not have particular demands, you can use generic air changes. The rate of dust creation for a particular mill Thanks for joining me on the BeerSmith Home Brewing Blog.

What are the ventilation requirements for malt drying? Clicking login or register below will redirect you to ProBrewer.com to start your login there. What if, for example, a fire had broken out after the Wigle Whiskey boiler explosion and spread to nearby apartments or other businesses?  It's not just the storage of spirits that's a hazard. Top Photograph: AP/Wide World. We are a 3 bbl nano with a 8 lb/min 2-roller mill. That puts some pressure on the fire service to figure out how they're going to regulate them.. Production brewery/microbrewery spaces can vary greatly. Please consider upgrading! This can lead to mold, permanent damage to the drywall, and other nasty issues. Webtion requirements include both a people component (to dilute contaminants from people and their activities) and an area component (to dilute contaminants from non-occupant-related It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. This tube will be sealed until below the liquid level. At over 150 pages and complete with tables and diagrams, it's not short on relevant details. Brewery Ventilation thread403-379650 HVACguy1985 (Mechanical) (OP) 6 Feb 15 19:02 Hi all I am designing brewery that has open fermenters and 1200 lbs/day CO2 produces. 456.3587 Total pounds of co2 released per day at full capacity. Filtration may be necessary for city water. One of the most dangerous aspects of distilling, Gerczysnki says, are the alcohol vapors that not only can emanate from the distilling equipment, but also from the barrels or casks of stored distillates.

It's not just the storage of spirits that's a hazard. Top Photograph: AP/Wide World. We are a 3 bbl nano with a 8 lb/min 2-roller mill. That puts some pressure on the fire service to figure out how they're going to regulate them.. Production brewery/microbrewery spaces can vary greatly. Please consider upgrading! This can lead to mold, permanent damage to the drywall, and other nasty issues. Webtion requirements include both a people component (to dilute contaminants from people and their activities) and an area component (to dilute contaminants from non-occupant-related It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. This tube will be sealed until below the liquid level. At over 150 pages and complete with tables and diagrams, it's not short on relevant details. Brewery Ventilation thread403-379650 HVACguy1985 (Mechanical) (OP) 6 Feb 15 19:02 Hi all I am designing brewery that has open fermenters and 1200 lbs/day CO2 produces. 456.3587 Total pounds of co2 released per day at full capacity. Filtration may be necessary for city water. One of the most dangerous aspects of distilling, Gerczysnki says, are the alcohol vapors that not only can emanate from the distilling equipment, but also from the barrels or casks of stored distillates.

Registration on or use of this site constitutes acceptance of our Privacy Policy. Elliot Gittleman, a fire protection engineer who consults for both the public and private sectors in the San Francisco area, tells the story of a distillery in Nevada that wanted to have visitors walk onto a deck overhanging the whiskey processing area. Your OP should have been posted in the Local Exhaust Ventilation forum. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO Different materials have a different propensity to combust. Thanks. Please let us know here why this post is inappropriate.

All times are GMT-7. Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. The lack of guidance within commonly used codes and standards has led to a lack of knowledge among craft distillers and the fire service around some of the dangers of these facilities, according to Gerczysnki.

Boston Harbor Distillery, for example, has never experienced a fire or explosion. The rate of dust creation for a particular mill isnt generally available. Despite all these measures, Forziati credits Boston Harbor Distillery's zero-incident track record to experience, citing distillery founder Rhonda Kallman's decade-plus in the business.