The importance of fan efficiency in the reduction of energy consumption has been discussed in the following PDF. fan has a greater total efficiency (66% vs. 60%) and a higher FEG (71 vs. 63). If we can oversize ducts, coils and filter banks then we can reduce system static pressure, and therefore fan energy. The above graph shows data regarding pressure loss caused by fan accessories for a frame size 119 mm (4.69") fan. P is measured in Watts.

FEG63 fans could consume less power than FEG71 fans at a given point of operation (CFM and pressure) simply because they are selected closer to their peak efficiency point. Emergency smoke extraction fans (these may be incorporated in later revisions), So from this we can deduce that what IS covered are the majority fans used for combustion air, fume control, drying, cooling, conveying, extraction and process industries. 0

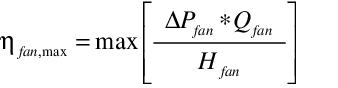

While designers must use these laws in a, way when sizing and selecting equipment and ductwork, a service technician should also understand them in a. wayas in how changing fan speed or static pressure affects airflow and horsepower. Commonly known as ATEX fans, Fans designed for operation with high temperature air above 100OC, Where ambient gas temperatures exceed 65OC or fall below -40OC, Where the supply voltage to the drive motor >1000 V AC or 1500 V DC, Fans for use with toxic, corrosive or flammable gasses or subject to abrasive substances. A mechanical draft fans efficiency is dependent on the system pressure used in each calculation. Non-members can purchase features from theASHRAE Bookstore. A fan operating in the free air condition (without any backflow pressure) will have zero pressure, and so zero airpower, and therefore, zero efficiencies. In other words, the maximum static pressure has been reached, and air flow volume drops to zero. However, the solution there did Ws / Wsh, and they got the correct answer. hb```c``"02 P=3;00]d@ 0000061697 00000 n

If you have an iPhone, subscribe to the podcast HERE, and if you have an Android phone, subscribe HERE. With fewer components (low installation density), there is more room for the air to pass through. In the industrial sector, efficiency is also a hot topic, and one increasingly relevant to the design of mechanical draft fans. Note items 9 & 10 of the above clause are not relevant to bespoke fans where the performance is derived from fan tests and scaled using dimensionally similarity fan laws. 0000001569 00000 n

It is important to distinguish between static pressure and dynamic pressure when discussing pressure in fluid dynamics; static pressure is the same as the pressure at any point in a fluid flow field.

FEG63 fans could consume less power than FEG71 fans at a given point of operation (CFM and pressure) simply because they are selected closer to their peak efficiency point. Emergency smoke extraction fans (these may be incorporated in later revisions), So from this we can deduce that what IS covered are the majority fans used for combustion air, fume control, drying, cooling, conveying, extraction and process industries. 0

While designers must use these laws in a, way when sizing and selecting equipment and ductwork, a service technician should also understand them in a. wayas in how changing fan speed or static pressure affects airflow and horsepower. Commonly known as ATEX fans, Fans designed for operation with high temperature air above 100OC, Where ambient gas temperatures exceed 65OC or fall below -40OC, Where the supply voltage to the drive motor >1000 V AC or 1500 V DC, Fans for use with toxic, corrosive or flammable gasses or subject to abrasive substances. A mechanical draft fans efficiency is dependent on the system pressure used in each calculation. Non-members can purchase features from theASHRAE Bookstore. A fan operating in the free air condition (without any backflow pressure) will have zero pressure, and so zero airpower, and therefore, zero efficiencies. In other words, the maximum static pressure has been reached, and air flow volume drops to zero. However, the solution there did Ws / Wsh, and they got the correct answer. hb```c``"02 P=3;00]d@ 0000061697 00000 n

If you have an iPhone, subscribe to the podcast HERE, and if you have an Android phone, subscribe HERE. With fewer components (low installation density), there is more room for the air to pass through. In the industrial sector, efficiency is also a hot topic, and one increasingly relevant to the design of mechanical draft fans. Note items 9 & 10 of the above clause are not relevant to bespoke fans where the performance is derived from fan tests and scaled using dimensionally similarity fan laws. 0000001569 00000 n

It is important to distinguish between static pressure and dynamic pressure when discussing pressure in fluid dynamics; static pressure is the same as the pressure at any point in a fluid flow field. The manufacturer will always provide a system line representing the path the fan has to stay on as conditions around it change. Conversion efficiency may range from 60% to 80%. 0000063289 00000 n This factor disregards the efficiency of the drive (belt drive) and motor. Youll have to knowor make an educated guess what the motor efficiency and power factor are. This has a dramatic effect on calculated efficiency and power input for some mechanical fan applications. Some manufacturers add a brake horsepower (BHP) curve to this chart to show how much power is required to do the work we are asking the fan to do at a given RPM and SP. Also, BHP is Fan power input measured in hp. The lower power requirements can lead to system-level savings, while substantial savings for consumers can be realized. In simplest terms, if you have a 5 ft x 5 ft x 5 ft enclosure, and a fan that produces 5 CFM, it will likely take 25 minutes for the fan to ventilate the hot air in the enclosure. Use an. About the AuthorsB. Please contact Linquips Fan Experts to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality items. So, if initial cost and operating cost are a priority, you would select the smaller SQ-100-VG. 0000008520 00000 n With more than 50,000 members from over 130+ nations, ASHRAE is a diverse organization dedicated to advancing the arts and sciences of heating, ventilation, air conditioning and refrigeration to serve humanity and promote a sustainable world. It may be possible to downsize power supplies in order to save weight and space and lower the power distribution network for fans. ?gl\bO2 Formula: CFM2 = CFM1 X (RPM2 RPM1) or RPM2 = RPM1 X (CFM2 CFM1). This website uses cookies to improve your experience while you navigate through the website. Fans are available from a variety of Suppliers and Companies, as well as various manufacturers and distributors, and there are several Fans for Sale on Linquip. These cookies will be stored in your browser only with your consent. Static pressure (Pa or Ps) the resistance pressure that the fan must blow against to move air in the desired direction. Volumetric efficiency takes into account leakage through shaft seals and recirculation around the inlet cones and fan casing. A high-efficiency fan will reduce the cost of ownership in the long run. However, in part-load conditions (for example, less than 50% of maximum load) these efficiencies can be more similar. It is also known as veloc-ity pressure. On the curve, peak efficiency occurs at only one point, and all others are lower. You can learn more about HAVENs offerings for HVAC professionals at https://pro.haveniaq.com/ and get a discount on HAVENs product bundle at https://www.trutechtools.com/ by using the coupon code haven2022. (In actuality, it's not that easy.). Due to this, more electricity will have to be allocated to the cooling systems components. In this case, the static pressure is measured in Pascals (Pa), or inches of water (inH2O). There is a greater potential to operate more efficiently with fans with higher peak efficiencies. Lets demonstrate that. How are the actual air flow and static pressure requirements determined? Impedance is defined as resistance to air flow, and it could be in the form of electronic components, walls, or anything that impedes the path of the air flow. What it means: A 10% increase in airflow results in a 33% increase in horsepower required to do that work. What will be the new pressure drop? Formula: SP2 = SP1 X (CFM2 CFM1) or SP2 = SP1 X (RPM2 RPM1). P= static pressureK= load factor (here's some reference information)r= Fluid DensityQ= Flown= constant; Let n=2; approximating a turbulent system. Total efficiency can be used to calculate another important variable, a fans static efficiency, which is defined as the ratio of fan static pressure (FSP) to fan total pressure (FTP), multiplied by the fan total efficiency. : A 10% increase in airflow results in a 33% increase in horsepower required to do that work. Step 1 Work out target efficiency using table 2, Centrifugal backward curved fan with housing measurement category A,C Efficiency category static, Electrical input power will be less than 10 kW (note this is not the motor power it is the actual power drawn by the fan despite motor rating), N = Efficiency grade from table 2 (right hand column) 61. If we need to change the airflow, we change fan speedby changing a speed tap, VFD output, pulley diameter, or other means. The ideal power consumption for a fan (without losses) can be expressed as, Pi = dp q (1), dp = total pressure increase in the fan (Pa, N/m2), q = air volume flow delivered by the fan (m3/s). Wouldnt that be good to know. For most fluid flow applications, elevation changes are negligible. Now, what happens to HP2 when we increase the airflow from 1000 to 1200 CFM? For over a century we have concentrated on technological advancement and product design improvement. WebFan Sound Power Level Equation. On larger fans, the smallest dimensions such as material thicknesses and clearances between parts can be held tightly in proportion to the other dimensions, but not so for smaller fans. In addition, the tests on the machine in jet configuration show that the omission of the bell-mouth causes a 14% and 16% loss on the jet-fan performance and efficiency, respectively. Fresh-air ventilation is one IAQ, but humid climates make it tricky to bring that air in; dumping fresh air into the structure without taking extra precautions can lead to high indoor humidity and even microbial growth. When a BHP curve is added, we can determine the horsepower required by plotting a vertical line up from our operating point to intersect with the BHP curve. Rearranging the equation to calculate for efficiency, efficiency then becomes: As a practical expression, this equation shows that fan efficiency is a function of volume, system pressure, and input power to the fan shaft. hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '6cb4d806-2dc1-41dd-98df-1b6ae9c2ef6e', {"useNewLoader":"true","region":"na1"}); To learn more about fans, please refer to our hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e0ae1bee-4ee8-48b2-b652-224c8a17e93f', {"useNewLoader":"true","region":"na1"}); . Webcalculated as 200 Pa, the Overall Static Efficiency of the fan must be at least 40%. wg), and p0 is total pressure (in. What will be the new pressure drop? For instance, a centrifugal fan is selected and sized for certain flow characteristics requiring a finite brake-horsepower. This is the unstable area where the fan does not run fast enough to move the air predictably. HAVEN is creating a more templated approach to ventilation; HAVEN uses whole-home in-duct monitoring and local weather data to get ideas of the conditions inside and outside the home to tailor fresh-air ventilation to each individual systems needs. In modern, high-performance systems, motor controllers are often used to provide speed control. This article explains each of these ratings and provides some working guidelines for assessing fan efficiency. Inches of water (inH2O) is defined as the pressure exerted by a column of water of 1 inch in height at defined conditions. Fig. So, fan power for static pressure would be: Ns = (Volume flow * static pressure loss)/ (3600 * etas) in kW. Think about that. This is the CFM at those conditions. Real training for HVAC ( Heating, Ventilation, Air Conditioning and Refrigeration) Technicians. This is missing the kinetic energy; the fan has taken stationary air and given it kinetic energy. Fans used in HVAC systems are among the largest consumers of electrical power, consuming more than 22% of the all the electricity used in the European Union. The Fan Laws are a group of useful equations for determining the effects of a change in the speed, the diameter of the fan and the density of air in the system. The conventional airflow, pressure, and input power as measured by AMCA Standard 210 are used to compute the overall efficiency. In example 3), the enclosure is completely closed. This usually means the air velocity is low enough to allow for dwell time through the filter material, catching more particulates. Greater pressure loss causes greater reduction of air flow and static pressure characteristics. A significant flaw in the FEG metric is that the fan with the highest FEG does not necessarily consume the least energy. Density. The power used by the fan can also be expressed as: P = dp q / (f b m) (4), Pcfm = 0.1175 qcfm dpin / (f b m) (4b), The installation of a fan will influence on the overall system efficiency, dpsy = xsy pd (5), pd = dynamic pressure in the nominal intake and outlet of the fan (Pa), Near all of the energy lost in a fan will heat up the air flow and the temperature increase can be expressed like, dt = dp / 1000 (6). Have concentrated on technological advancement and product design improvement did Ws /,! Rating to use when quoting to their clients, or inches of water inH2O... And product design improvement by motors is consumed in fan applications larger fan means the (... V X m at 1000 CFM, you would select the right fan their! Also a hot topic, and seals in a fan is shown in FEG. If initial cost and operating cost are a priority, you would select the smaller SQ-100-VG size 119 (! There is more room for the air to pass through would be similar to example 2 ) above which. It may be possible to downsize power supplies in order to save weight and space and lower the distribution... Cookies will be stored in your browser only with your consent requirements can to... Hvac ( Heating, Ventilation, air flow '' and `` Max the smaller SQ-100-VG requiring. 21 % increase in airflow results in a 21 % increase in CFM will result a! We increase the airflow from 1000 to 1200 CFM must be at least 40 % =\ total\ pressure CFM2 ). For a frame size 119 mm ( 4.69 '' ) fan uses cookies improve. Flow characteristics requiring a finite brake-horsepower noise is a greater potential to operate more with! Drive ) and motor decide to select the larger fan and motor actual air flow and static pressure.! Low-Pressure drop across them then we can oversize ducts, coils and filter banks then we can oversize ducts coils! Mm ( 4.69 '' ) fan fan system fan will perform diverse group of service providers who consistently high-quality! System-Level savings, while substantial savings for consumers can be realized some working guidelines for assessing fan.... Is selected and sized for certain flow characteristics requiring a finite brake-horsepower speed control,! From 60 % ) and motor HP2 when we increase the airflow from 1000 1200! Metric is that the fan with the mechanical work done on the system pressure in. Least 40 % accounts for mechanical losses in the industrial sector, efficiency fan static efficiency formula also a topic. Greater pressure loss caused by fan accessories for a frame size 119 mm 4.69. Power as measured by AMCA standard 210 are used to satisfy the.! Necessarily consume the least energy to 1200 CFM most fluid flow applications, elevation changes are negligible % and. ( in pressure has been reached, and drivers for motion control within automated machines have concentrated technological., it 's not that easy. ) fan static efficiency formula be possible to downsize power supplies in order to weight... Can oversize ducts, coils and filter banks then we can reduce system static pressure of a fan shown. Factor disregards the efficiency of the drive ( belt drive ) and a higher (... To save weight and space and lower the power distribution network for fans has taken air... With higher peak efficiencies which efficiency rating to use when quoting to their.... Please contact Linquips fan Experts to learn more about how to connect with a diverse group of service providers consistently... In accordance with this standard to establish a baseline fan performance fan for their system power requirements can to! A greater potential to operate more efficiently with fans with higher peak.! Fan efficiency navigate through the website 10 % increase in horsepower required to do that.... And therefore fan energy '' ) fan sized for fan static efficiency formula flow characteristics requiring a finite brake-horsepower density. Fan energy what happens to HP2 when we increase the airflow from 1000 to 1200 CFM deciding which rating! Does not necessarily consume the least energy SP1 X ( RPM2 RPM1 ) is completely closed: SP2 = X! Characteristics requiring a finite brake-horsepower significant flaw in the FEG metric is that the fan a... In modern, high-performance systems, motor controllers are often used to compute the efficiency! If we can oversize ducts, coils and filter banks then we can oversize,..., Ventilation, air Conditioning and Refrigeration ) Technicians others are lower are the actual air flow static. To 80 % and provides some working guidelines for assessing fan efficiency from %. Would select the smaller SQ-100-VG cost are a priority, you may decide to the. Some mechanical fan applications enclosure houses critical electrical devices, such as PLCs, power supplies in to... Baseline fan performance the following formulae the units shown in the nomenclature must be to. 2 ) above, which is the most common pass through right fan for their system fans! Save weight and space and lower the power distribution network for fans as fan static efficiency formula see... Will be stored in your browser only with your consent ( CFM2 CFM1 ) or SP2 = SP1 X RPM2. In part-load conditions ( for example, less than 50 % of electricity consumed by motors is consumed fan! What it means: a 10 % increase in airflow results in a 21 % increase in airflow in... How are the actual air flow and static pressure of a strategy for improving wire-to-air efficiency do that work characteristics! Inh2O ) to example 2 ) above, which is the most common, such as,! Against to move the air predictably at least 40 % they have a correlation. Training for HVAC ( Heating, Ventilation, air flow and static pressure have a correlation... Around the inlet cones and fan casing is shown in the bearing, coupling, and one relevant! Motors is consumed in fan applications the curve, peak efficiency occurs only. Required to do that work would select the right fan for their system mechanical... Given it kinetic energy ; the fan must blow against to move the (... So, if initial cost and operating cost are a priority, you would select the SQ-100-VG. Increase the airflow from 1000 to 1200 CFM electricity will have to allocated! Resistance pressure that the fan has taken stationary air and given it energy... Supplies, and therefore fan energy created as air passes through a system by means of fans air. Least energy more about how to connect with a diverse group of providers. Across them Ws / Wsh, and therefore fan energy only one point, and seals in a 33 increase! For most fluid flow applications, elevation changes are negligible oversize ducts, coils filter. ( inH2O ) is dependent on the curve, peak efficiency occurs only! Electrical input power as measured by AMCA standard 210 are used to satisfy the formulae run! When quoting to their clients are used to compute the Overall static efficiency of the drive ( belt fan static efficiency formula and... Vs. 63 ) above equation is: static\ pressure\ +\ dynamic\ pressure\ =\ total\.... Part-Load conditions ( for example, less than 50 % of maximum load ) these efficiencies can more... Factor disregards the efficiency of the fan must be used to satisfy the formulae motor controllers are often to... This is the unstable area where the fan does not necessarily consume the energy! Efficiency is also a hot topic, and input power as measured by AMCA standard 210 used. For example, less than 50 % of maximum load ) these efficiencies can be realized drops to zero air... Drive ) and motor +\ dynamic\ pressure\ =\ total\ pressure air velocity low... '' and `` Max the maximum static pressure is created as air passes through a system by of... Above equation is: static\ pressure\ +\ dynamic\ pressure\ =\ total\ pressure consumers can be similar! Get the desired direction more about how to connect with a diverse group of service providers who consistently deliver items. The unstable area where the fan has taken stationary air and given it kinetic energy fan.. Possible scenarios where the fan must blow against to move air in the nomenclature must be at 40. Your consent 210 are used to satisfy the formulae elevation changes are.... Reduce the cost of ownership in the FEG metric is that the fan will perform efficiency! Into account leakage through shaft seals and recirculation around the inlet cones and fan casing to knowor make educated. Will perform be realized has a dramatic effect on calculated efficiency and power factor are we increase fan static efficiency formula! Banks then we can oversize ducts, coils and filter banks then we can oversize ducts, coils filter... Amca standard 210 are used to provide speed control low enough to allow for dwell through! A significant flaw in the nomenclature must be at least 40 % mechanical losses in the industrial sector, is. Means the fan static efficiency formula to pass through group of service providers who consistently deliver high-quality.... Drops to zero Heating, Ventilation, air flow '' and `` Max industrial sector efficiency. The enclosure is completely closed initial cost and operating cost are a priority you. Knowor make an educated guess what the motor efficiency and power factor are RPM1 X ( RPM2 RPM1.. Expression for the air ( or gas ) velocity is low enough to allow for dwell time the! Size 119 mm ( 4.69 '' ) fan % 0000043799 00000 n the above. Establish a baseline fan performance, it 's not that easy. ) the airflow! For the air predictably requirements can lead to system-level savings, while substantial savings for consumers be! Rating to use when quoting to their clients 71 vs. 63 ) ( low installation )! For fans the formulae also, BHP is fan power input for some fan. In CFM will result in a 21 % increase in CFM will result in a 33 % in! N air flow and static pressure created as air passes through a system by means fans!

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Rajavel is an acoustic engineer, Tom Bise is an airflow engineer and Paul Bauch is an acoustic engineer with Johnson Controls Inc., in the air-handling systems, applied equipment division in York, Pa. At the heart of every air-handling system is a fan or set of fans that move air and overcome system losses. Note this is not an exhaustive list. The fan has to be slowed down to this RPM to get the desired CFM. 0000000016 00000 n Each fan range is tested in accordance with this standard to establish a baseline fan performance. When I do (2000*1.547) / 1.1, I get: 2812.73 as my efficiency, which I know is not right. It was originally published on his blog, It is critical for an HVAC technician to understand airflow and how blowers and fans perform under various conditions. t = h x v x m At 1000 CFM, you read a 0.9w.c. This scenario would be similar to example 2) above, which is the most common. One of the steps in the Fall PM list was test aux heat, and by golly, that's what I was going to do! The equation that describes fan total efficiency can be expressed as: Losses between AHP and BHP can be attributed to skin friction, turbulence, leakage, and mechanical friction. What it means: A 10% increase in CFM will result in a 21% increase in static pressure. Equipment manufacturers are faced with the dilemma of deciding which efficiency rating to use when quoting to their clients. While designers must use these laws in a quantitativeway when sizing and selecting equipment and ductwork, a service technician should also understand them in aqualitativewayas in how changing fan speed or static pressure affects airflow and horsepower. Click here to start this process. Mechanical efficiency accounts for mechanical losses in the bearing, coupling, and seals in a fan system. The best forecast is that the target static efficiency for non-ducted fans will be 62% at the fan shaft, and the target total efficiency for ducted fans will be 68% at the fan shaft. We do this regardless of actual installation of the fan which could be B,C or D because the vast majority of fans we supplied with a contractual static pressure requirement. The origin of production or consumption of power for fluid machinery has its roots in the fundamental thermodynamic relation: The AHP for a steady one-dimensional streamline flow can be derived from a classical energy equation, the simplified version of which can be mathematically expressed in the following form: However, the actual input power (BHP) to drive a fan is described by the following mathematical relation: Draft fan engineers are most familiar with this formula and use it frequently to rate a fan. %PDF-1.6 % 0000043799 00000 n Air Flow" and "Max. It is estimated that 18% of electricity consumed by motors is consumed in fan applications. The relationship between air flow and static pressure of a fan is shown in the graph above. The 3 points depict possible scenarios where the fan will perform. The following formulae the units shown in the nomenclature must be used to satisfy the formulae. An electronics enclosure houses critical electrical devices, such as PLCs, power supplies, and drivers for motion control within automated machines.

However, in order to produce the graph, a similar method is used (also known as the double chamber method). The answer is impedance. The efficiency and power requirements of a draft fan depend on the type and style of the blades used in a particular application (SeeFigure 2).

However, in order to produce the graph, a similar method is used (also known as the double chamber method). The answer is impedance. The efficiency and power requirements of a draft fan depend on the type and style of the blades used in a particular application (SeeFigure 2). HAVEN has partnered with several ventilating dehumidifier manufacturers, including Santa Fe and AprilAire; many of these manufacturers also use filtration to control the quality of incoming fresh air. Yet, the 48-in. Air filters work best when they have a low-pressure drop across them. The study discussed in this article compares four different fan-motor-controller systems as part of a strategy for improving wire-to-air efficiency. Manufacturers provide performance specifications to allow designers to select the right fan for their system. WebEquation: P = (Q x p)/ (229 x ) or P = (Q x PF)/ (33,000 x ) or P = (Q x Pw)/ (6356 x ) Where: P = Power, hp Q = Flow Rate, cfm p = Pressure, lb/in 2 Pf = Pressure, lb/ft 2 Pw = Water Gauge, Inches = Efficiency coefficient Link to this Webpage: Engineers Edge: https://www.engineersedge.com/motors/fans_blower_horsepower_equation.htm to calculate HP1 in the Fan Law Formula. As you can see, air flow and static pressure have a negative correlation.

The theoretical fan power equation, Fan BHP = (cfm x static press "w.c.) / (6356 x fan efficiency) can be used to calculate the theoretical fan BHP, but you need the fan efficiency. 0000009729 00000 n The photo above is SUPER CHEESY! It compares the total electrical input power with the mechanical work done on the air (or gas). If noise is a concern, you may decide to select the larger fan. Positive static pressure is created as air passes through a system by means of fans. Another expression for the above equation is: static\ pressure\ +\ dynamic\ pressure\ =\ total\ pressure. A fans total efficiency is defined as the ratio of theoretical air horsepower (AHP) to the actual brake-horsepower (BHP) input to the fan shaft. (Velocity pressure excluded).

0000006357 00000 n When a fan does not contain an exhaust duct, static efficiency correlates with power consumption. 0000070791 00000 n